Detects and corrects programming issues prior to cutting any material

LaserCoil Technologies LLC has announced its Virtual Controller, which can run the company’s coil-fed laser blanking systems virtually using true production rates and enabling the optimization of nesting patterns for maximum material utilization or cycle times, as well as detecting any programming issues prior to running a program using actual material. An enhancement to the company’s LaserCoilCAM software, it only takes a matter of minutes to create a program and run it on the Virtual Controller. The LaserCoilCAM software allows operators, even those with little experience, to quickly create an optimized program.

How It Works: Material parameters (type and thickness) are selected. Critical cutting parameters are imported based on the material parameters. A 2D CAD file is imported, and the nesting pattern is created for a material width that optimizes material usage, or the programmer can input a specific coil width that they need to nest the part in. The programmer can also select any grain constraint requirement during the nesting process.

The programmer then selects which features should be cut with each laser cutting head, as well as selecting the order that each head produces these features. The program can then be run visually in the CAD/CAM portion to verify these cutting features and their order for each cutting head with a single click of a button. The program is now complete.

This prepared program can now be run through the LaserCoilCAM virtual controller. Running this program will identify any programming errors that would cause warnings or faults during production, as well as proving cycle time for that particular program. All of the actual machine parameters from the customer’s installation are captured and mimicked in the virtual controller.

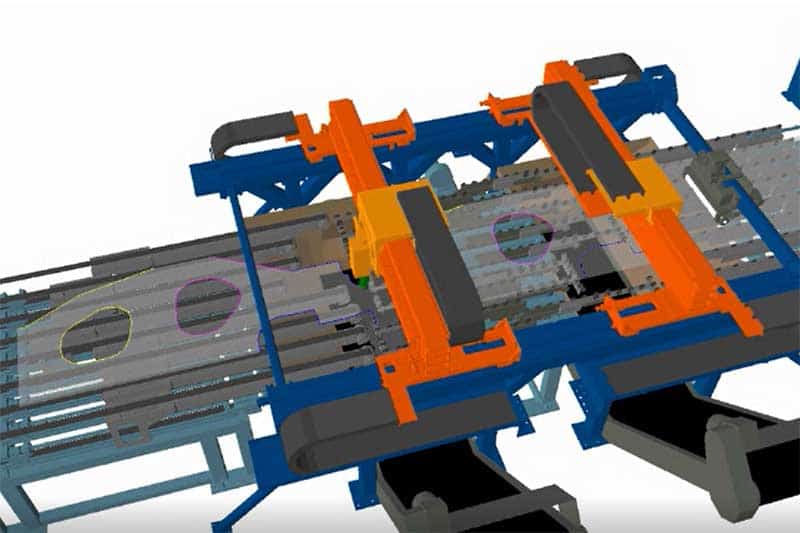

By laser cutting direct from coil stock, LaserCoil systems provide a fast and flexible approach to blanking that is well-suited for production environments running multiple blank profiles and mixed material types. The systems can handle coil stock up to 2.1 m wide in any length, and can process aluminum, mild steel, advanced high-strength steels, hot stamped and surface sensitive materials, as well as structural components.

For more information on this approach to laser cutting of coil strip, visit www.lasercoil.com or watch the LaserCoil CAM video.